Building a Circular Economy: Implementing Closed-Loop Systems in Manufacturing

Traditional manufacturing processes pose several challenges that can hinder efficiency and sustainability within a production system. One major issue is the high level of waste generated during these processes. This waste can come in the form of materials, energy, or resources, all of which contribute to environmental degradation and increased production costs.

Additionally, traditional manufacturing processes often lack flexibility, making it difficult for companies to adapt to changes in demand or product specifications. This rigidity can lead to inventory stockpiles, production delays, and ultimately, customer dissatisfaction. In a rapidly evolving market, the inability to quickly adjust production processes can put manufacturers at a significant disadvantage compared to competitors utilizing more agile methods.

Benefits of Implementing Closed-Loop Systems

Implementing closed-loop systems in manufacturing processes can lead to significant benefits for both businesses and the environment. By reusing materials and reducing waste, companies can cut down on production costs and minimize their environmental impact. Closed-loop systems also promote a more sustainable approach to manufacturing, as they help conserve resources and decrease the need for extracting raw materials.

Additionally, closed-loop systems can improve the overall efficiency of production processes. By recycling materials within a closed system, companies can streamline their operations and optimize resource utilization. This not only results in cost savings but also enhances the resilience of supply chains, making businesses more adaptable to fluctuations in resource availability.

Strategies for Designing Sustainable Products

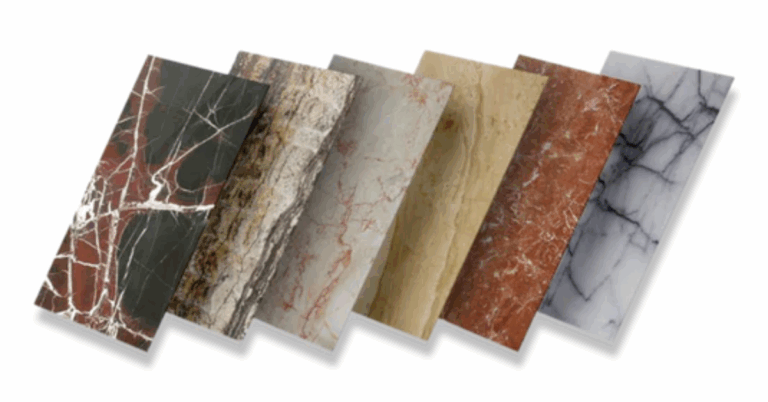

Designing sustainable products is an essential endeavor in today’s world where environmental consciousness is on the rise. One key aspect to consider is the materials used in production. Opting for renewable, recyclable, or biodegradable materials can greatly reduce the environmental impact of a product throughout its life cycle.

Furthermore, the design phase should prioritize longevity and repairability. By creating products that are durable and easy to fix, the need for constant replacements and waste can be minimized. Including features that allow for disassembly and component replacement can also contribute to the longevity of the product, ultimately leading to a more sustainable design.